In modern industry, the integrity and safety of materials and components are paramount. Flaws, cracks, and other defects can lead to catastrophic failures, posing significant risks to both personnel and operations.

Traditional non-destructive testing (NDT) methods have long been the standard, but the advent of advanced technologies has introduced more efficient and precise alternatives. Among these, phased array inspection stands out as a superior method.

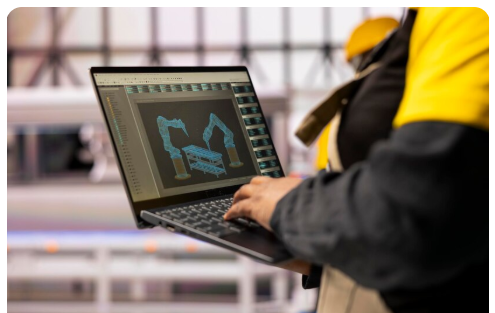

This technique uses a multi-element probe to generate a steerable ultrasonic beam, providing a detailed and comprehensive view of a material’s internal structure.

For industries ranging from aerospace to energy, a move to phased array inspection offers numerous advantages. This article explores the key benefits of incorporating this advanced service.

Enhanced Accuracy and Flaw Detection

One of the most significant benefits of phased array inspection is its enhanced accuracy in detecting defects. The technology allows for the electronic steering and focusing of the ultrasonic beam, enabling a detailed scan of complex geometries and hard-to-reach areas.

This precision means that small or irregularly shaped flaws, which might be missed by conventional single-element probes, can be reliably identified.

The ability to create a real-time, high-resolution image of the internal structure provides a level of detail that is crucial for making informed decisions about a component’s integrity.

Increased Inspection Speed

Time is a critical factor in industrial maintenance and quality control. Phased array inspection significantly reduces the time required for inspections compared to traditional methods.

By using a single probe with multiple elements, it can scan a large area with a single pass, eliminating the need for multiple passes and different-angle setups. The electronic steering of the beam allows for a rapid sweep of the entire volume, making it a much more efficient process.

This increased speed translates into less downtime for equipment and more productive maintenance schedules.

Versatility for Complex Geometries

Traditional ultrasonic testing can be challenging on components with complex shapes, such as curved surfaces, welds, and irregular castings. The flexibility of phased array inspection makes it exceptionally well-suited for these applications.

The ability to adjust the beam angle and focus allows technicians to inspect various parts from a single position, adapting to the specific geometry of the component.

This versatility means that a wide range of parts can be inspected with a single system, providing a comprehensive solution for diverse industrial needs.

Comprehensive Data and Documentation

Phased array inspection systems generate extensive data, including detailed A-scans, B-scans, and C-scans, which can be stored and analyzed.

This digital record provides a comprehensive history of the component’s condition, making it easy to track changes over time and document compliance with regulatory standards.

The ability to archive and retrieve this data is invaluable for long-term asset management and quality assurance. The detailed reports generated from a phased array inspection offer clear evidence of a component’s integrity.

Cost-Effectiveness and Reduced Manpower

While the initial investment in phased array equipment may be higher than traditional tools, the long-term cost benefits are considerable. The increased speed and efficiency of phased array inspection mean that fewer hours are spent on a single inspection, reducing labor costs.

The comprehensive nature of the scan also reduces the need for multiple inspection methods, consolidating the process into a single, more economical service. This streamlined approach makes it a highly cost-effective solution for large-scale projects.